IML & PackagingIntelligence between start and stop.

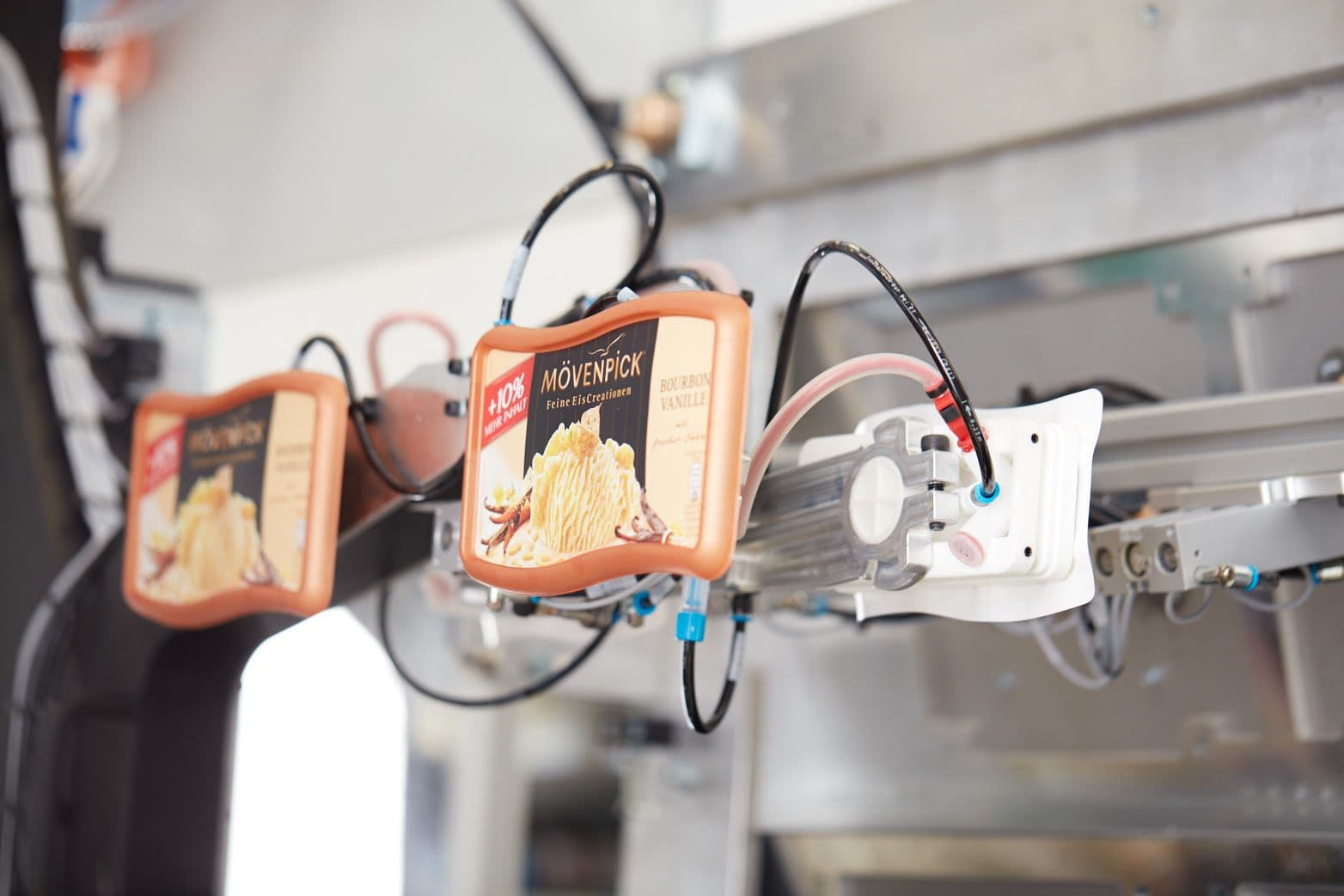

In-mould labeling (IML) uses robots to load labels directly into the injection molding tool.

The label is molded into the product, becoming an integrated part of it. This technology enables photo-quality results and is seeing rapid adoption across the industry.

The products are often packaging materials for the food industry, but can also include other types of packaging solutions.

Production runs at high speed, frequently using multi-cavity molds. With cycle times of just a few seconds, we load large numbers of labels while simultaneously removing the same number of finished products.

Labels, perfectly placed

For the label to be positioned perfectly on the product, a high level of precision and stability is required throughout the entire process.

We are specialists in the IML process and place particular emphasis on the design of the label loading tools – the so-called “dummies”.