Machine TendingAutomated machine tending for efficient, balanced production flows.

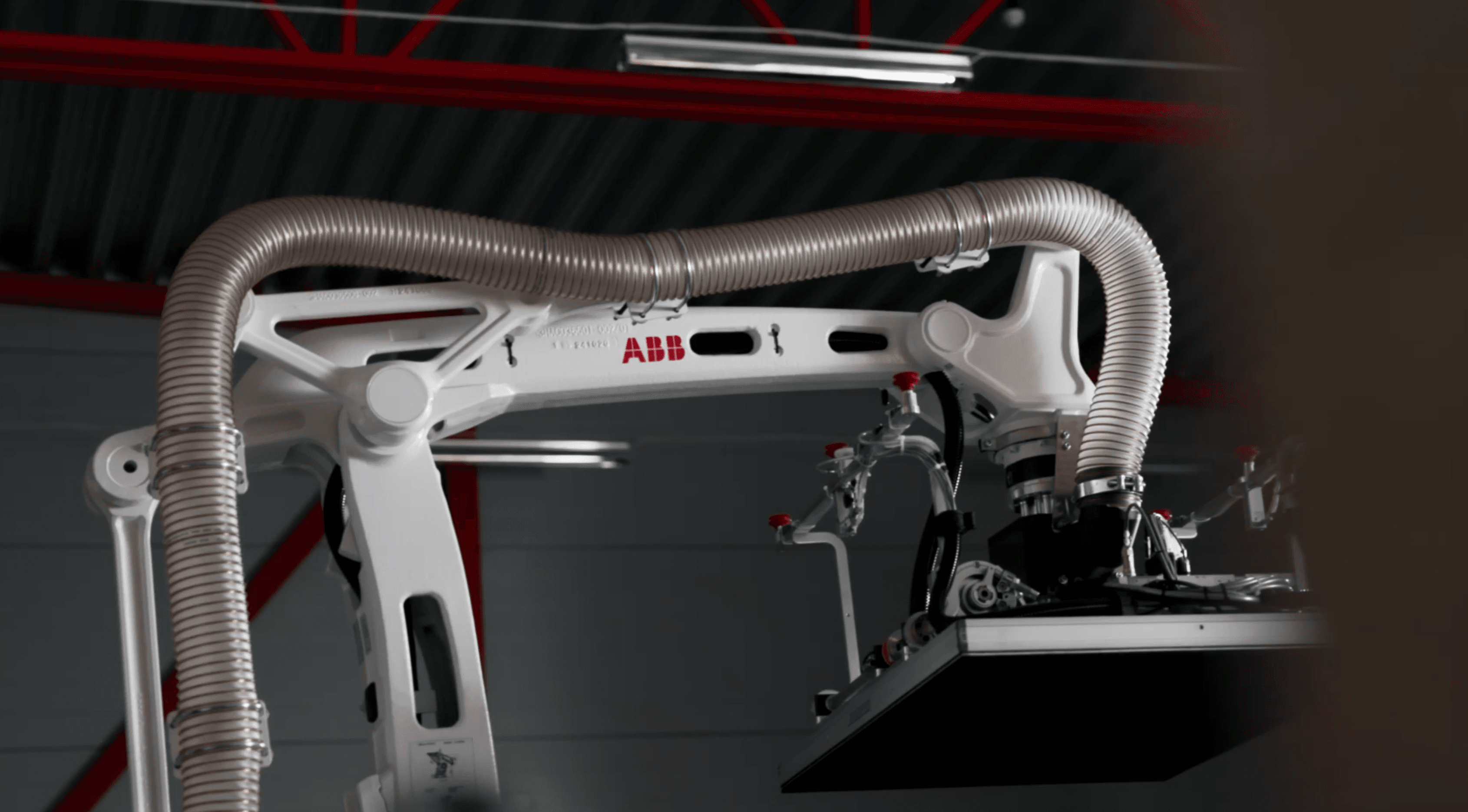

Machine tending means robots load machines with parts for processing and then unload them again.

Machine tending has many advantages

In machining applications, robots can load and unload lathes and multi-operation machining centers.

High availability is one of the most tangible benefits of machine tending. Machines run longer and more reliably. Quality improves, efficiency increases, and valuable time is freed up.

Another advantage is that part orientation can be maintained, making it possible to add subsequent steps such as deburring, marking, or assembly. This allows a fully finished product to be delivered directly at the machine.

CNC machines – and the bigger picture

Machining is one of our core areas of expertise. Thanks to long experience and close collaboration with Swedish manufacturing companies, we’ve built deep process knowledge over time. The high demands placed by Swedish industry on availability and control at every stage have driven our development and taught us what truly makes a difference.

The more complete a solution we can create around CNC machines, the better. That’s why 3BG is also happy to supply fixtures for clamping parts in machining equipment. When automation can also include deburring, marking, or washing, we contribute our process expertise there as well.

The overall control layer often involves communication with business systems and various types of performance and follow-up metrics. These elements of the bigger picture are just as important to refine.